OFFER

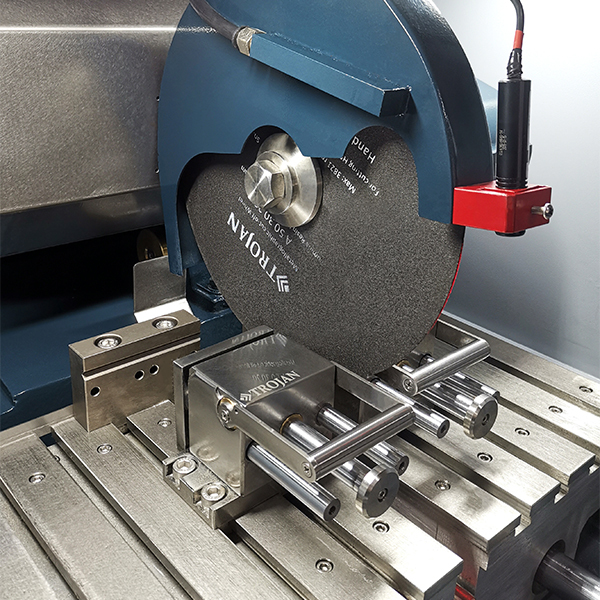

Automatic cutter BETA-300 PRO

● 20 preset cutting parameters

● Cutting in the X-Y-Z axis with joystick control

● Multiple cutting modes

● Push-up – sliding door design

| Max blade diameter | 300 mm |

|---|---|

| Blade diameter min | 200 mm |

| Max cutting depth | 110 mm |

| Shank diameter | 32 mm |

| Max cutting size HxD | 80 × 200 mm |

| Z axis feed (up-down) | 150 mm |

| Y axis feed (front - back) | 220 mm |

| X axis feed (right - left) | 100 mm |

| Worktable dimension | 280 × 536 (636) mm |

| The width of the T-slot mounting | 12 mm |

| Rotation speed | up to 3500 rpm |

| Control panel | 7 inch touch screen |

| Cutting method | Smart cutting AUTO Cutting up / down in the Z axis AUTO Table feed in Y axis AUTO Pulse cutting Y-axis, Z-axis Step cutting YES |

| Feed speed | 0.02 – 3 mm / s |

| Laser leveling | yes |

| Weight | 367 kg |

| Dimensions WxDxH | 940x920x1450 (1860) mm |

| Recirculating coolant | 80 liters |